- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Home

- Our Brands

- Koike

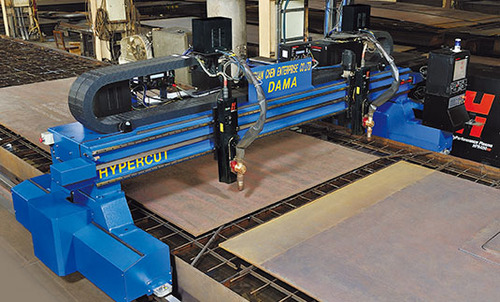

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

Description

KOIKE's latest economic solution for Oxy-fuel & Air Plasma Cutting

FLEXIKEN is KOIKE’s latest economic cutting solution, which can be widely applied to several industries, from small cutting shops to some applications on machinery manufacturing and shipbuilding industry. Designed and manufactured under KOIKE's finest standards, FLEXIKEN has a rigid, stable and compact gantry structure, Precision CP Rack & Pinion drive with Gear Box, which assure high accuracy and cutting quality.

FLEXIKEN performs high precision and high speed cutting in both Oxy-fuel and Plasma cutting, delivering excellent cutting quality.

Although its standard cutting device is Oxy-Fuel, customer can also opt to add a Plasma cutting system to the machine, and the exclusive Torch Parking will give customer the possibility to easily switch manually between Oxy-Fuel and Plasma Cutting whenever it is necessary.

It’s equipped with the user-friendly KOIKE D430 Controller with a 10” LCD Color Display that providing a very easy operation, 53 built-in shapes and highly customizable parameters.

Features

- Dual Drive with high precision Rail, and Rack & Pinion

- Economic solution for high accuracy and cutting performance

- Equipped with KOIKE D430 CNC with in-built AVC

- KOIKE high speed divergent nozzles for oxy-fuel cutting

- Prepared for Air Plasma System

- Low-Backlash planetary reduction gear-boxes for all axes

- Rigid, stable and compact gantry design

- 2 Emergency Stop Switch, located on each sides of machine

- Comes standard with KOIKE CAD/CAM software, "FLEXI-CAM"

Technical specifications

| FLEXIKEN | ||||

| Model Name | FLEXIKEN 5.0 | FLEXIKEN 5.0 (XL) | FLEXIKEN 7.0 | FLEXIKEN 7.0 (XL) |

| Rail Span (mm) | 1,940 | 1,940 | 2,606 | 2,606 |

| Rail Length (mm) | 4,000 | 7,500 | 4,000 | 7,500 |

| Effective Cutting Width (mm) | 1,520 | 1,520 | 2,020 | 2,020 |

| Effective Cutting Length (mm) | 3,100 | 6,300 | 3,100 | 6,300 |

| Machine Structure | Gantry Bridge / Dual Drive (Rack & Pinion) | |||

| Rail Type | T-Type Elevator Rail | |||

| Rapid Drive Speed (mm/min) | 8,000 | |||

| Cutting Speed (mm/min) | 50 to 6,000 | |||

| Input Power Supply | 1-Phase, 240V ±10% 50/60Hz (for different power supply please contact us) | |||

| CNC | KOIKE CNC D430 – In-built AVC | |||

| Torch Block Capacity | 1 Oxy-Fuel or 1 Plasma (Interchangeable) | |||

| Gantry Parking | 850mm (Parking space) | |||

| Plasma System | Air Plasma System (Hypertherm Powermax Series) | |||