- Home

- Our Brands

- Koike

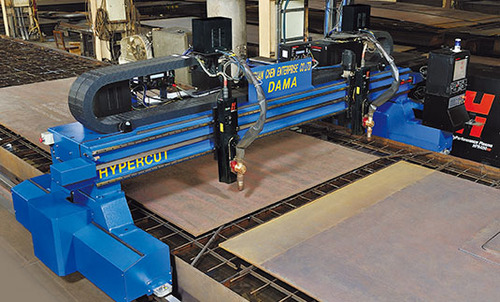

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

Features

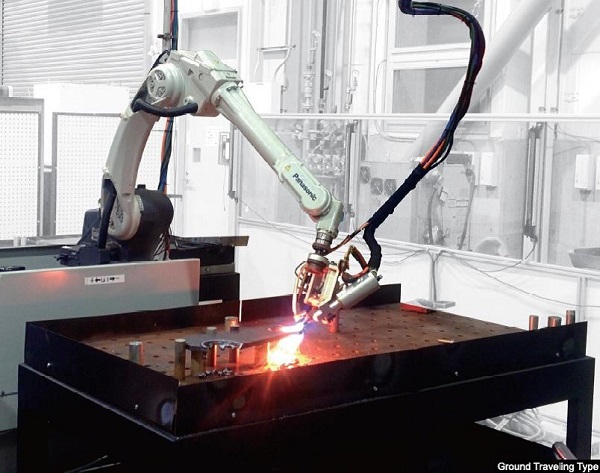

- By adopting the 6axis articulated robot, high qualitty and automated curved bevel cutting is possible.

- Offline automatic programming is possible, it is perfect choice for multi-product production.

- A pin Cutting Table is used to support the work piece, there is no need for any work piece jig.

- The position deviation at the time of workpiece setting is corrected by the mounting of the touch sensor.

- Cutting of large work piece is also possible by using the traveling Slider and Overhanging System.

Description

Specialized in the flame beveling of steel shapes commonly used in the construction machinery and shipbuilding industry. By combining a work piece touch sensor the part position deviation can be corrected. High quality bevel cut is provided even in shapes that includes arcs by using the 6-axis articulated robot. The KOIKE’s 2D CAD/CAM software “KAP” is available in this system, and program for the robot can be created from the parts data. By the connecting with KAP interoperability achieved is similar to a NC Cutting Machine, solving the problem of decrease of production efficiency due to the teaching work in the conventional robot operation.

Technical specifications

| Bevel Master | |||

| Structure | Fixed Type | Ground Traveling Type | Ceiling Mounted Type |

| Robot Type | Panasonic TL-1800 | ||

| Touch Sensor | Sensing Probe Type | ||

| Number of Motion Axis | 6-axis | 7-axis | |

| Effective Cutting Thickness | 1000×1000mm | 1000×4000mm | 2000×6000mm |

| Max. Cutting Thickness | 50mm (Please consult in case of thick plate more than 50mm) | ||

| Max. Bevel Angle | 45° Positive/Negative | ||

| Fuel Gas for Cutting | LPG or SUPERCUT H (Hydrogen mixed gas) | ||

| Hi/Low Switch | Yes | ||