- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

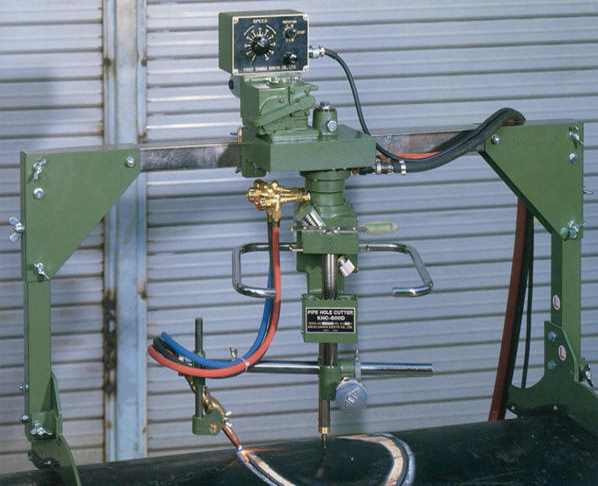

Description

The KHC-600D is a portable automatic oxy-fuel pipe hole cutting machine. The main application is the accurate cutting of holes with or without bevel in pipes, high-pressure storage tanks and heat exchangers. An eccentric mechanism guarantees an exact adjustment of the stroke (vertical travel of the torch). The rotational joint at the gas supply prevents entangling hoses and a repositioning of the machine to its home position.

Features

- Compact design

- Cuts a vessel from the inside as well as from the outside

- Easy positioning for cutting by the use of centering pin (circle diameter 60 - 600 mm)

- Bevel cuts till 45° possible

- No entangling hoses due to rotational joint

Scope of delivery

- Cutting machine KHC-600D

- Cutting nozzles (5-30 mm material thickness)

- Connecting lead (5 m)

- Tool set

- Operation instructions

Technical specifications

| KHC-600D | |

| Cutting thickness | 5-50 mm |

| Bevel Cutting Angle | 0-45° |

| Effective Circle Cutting diameter | φ80-600 mm |

| Min. Main pipe dia. | φ800mm |

| Vertical torch stroke | 0-100 mm |

| Ratio between Branch and Main pipe dia. | Minimum 1 : 2 or more |

| Speed Control Method | PWM control |

| Cutting speed | 100-700mm/min |

| Machine dimensions (WxHxD) | 500 mm x 760 mm x 1050 mm |

| Type of gas | Acetylene, propane |

| Weight | 26.0 kg |