- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Home

- Our Brands

- Koike

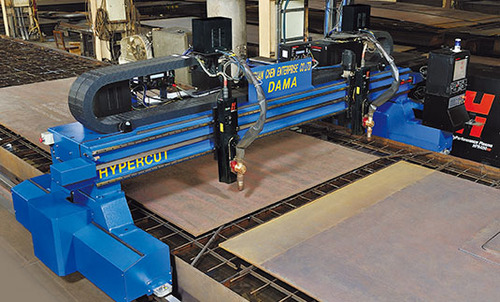

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

Description

CAD/CAM Software developed based on the rich experience of KOIKE in oxy-fuel, plasma, and laser cutting.

Special processes such as Corner Process, Bevel Cutting, Water Drainage Cutting can be configured by adding the customer's know-how and achieving product accuracy. It can also be connected with production control, operation management, steel stock management system.

Production Control

Delivery Date, Customers, and Products Models can be controlled. Models, Weightnand Cutting Length records can be outputted in a .csv file.

Operation Management

Operation conditions such as cutting, marking, fast-forward time, are collected from the Cutting Machine and outputted in a .csv file.

Steel Stock Managemant

Material's Stock, Remnant Plate Processing, Materials Shape can be easily managed, and cutting achieves excellent yield. Material, Remnant Plate Processing, and Scrap can be managed uniformly.

Features

- System maximize he Cutting Machine processing performance.

- Fine cutting is achieved meeting the customer needs.

- Special cuttings such as bevel cutting are available.

- Cutting Machine can be connected to cutting schedule management and performance management.

- Various traceability enhancement are available.

Function List

| KAP8030N Ver.5 | |||||

| Free Parts Shape Creation | Automatic Sequence | ||||

| DXF/DWG Conversion | Common Line Cutting | ||||

| Basic Shapes Pattern(55types) | Cutting/Cutting Ref. Pattern Creation | ||||

| Automatic Dimension Display | Multipple Torch Cutting Route Creation | ||||

| Automatic Nesting | Cutting Route Interference Check | ||||

| Yield Display | Remnant Plate Processing Managemant | ||||

| Min. Required Base Material Indexing | NC Date Transfer | ||||

| CVC Date Output | |||||