- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Home

- Our Brands

- Koike

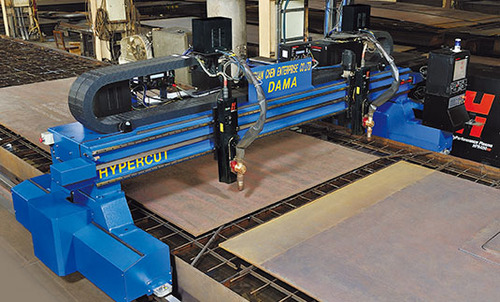

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Features

- Specifications

- Video

- HDC-2020 is high efficiency high production drilling machine with high speed coolant thru spindle.

- HDC-2020 is suitable for tube plate drilling, boring, grooving, milling and tapping.

- CNC system: Dama-Syntec Special purpose CNC system, Windows CE base for plate drilling jobs with ease operation interface.

- X, X’ Dual axis AC servo motor, double ball-screw, four linear guide.

Y axis AC servo motor, ball-screw, Linear guide.

Z Axis AC servo motor, ball-screw, linear guide. - Rigid BT 40 coolant thru spindle up to 2000 rpm, drilling diameter from 6~50mm and thickness up to 100mm.

- Adopting with spindle air cooling system & air positive pressure system to protect the spindle.

- Provides a macro for three point to decide a circle, easy looking for a center for round parts.

- Provides M8~M24 rigid tapping and milling thread function for over M24 thread.

- Provides tool life manage function to keep the drilling quality.

- Provides the DXF and G, M code file transfer easy CNC part program produce.

| Model | HDC-2020 | |

| Max size of work-piece | width*length(mm) | 2000*2000 |

| Max thicknes | 100 mm | |

| IPC CNC controller (Syntec 10B-STD-B-K-4425M) | 110.4” LCD color display Part program loading:

|

|

| High Speed High precision spindle | BT 40 spindle Rotary coupling, standard for cooling-thru tools. Adopting with spindle air cooling system & air positive pressure system to protect the spindle | |

| Drilling capability (Drill diameter) | Ø6~ Ø50 | |

| Tapping capability | M8~M24 | |

| Spindle servo motor 20HP | Rated torque | 284 |

| Rpm | 200~2000 | |

| ratio | 1/2 | |

| Longitudinal movement of gantry (X & XX axis) | Rapid speed | 12 m/min |

| Guide way | Linear guide way | |

| Transmission | Ball screw (∮ 48) double side) | |

| Servo motor power (KW) | 1KW X 2 PCS | |

| Transverse movement of spindle (Y axis) | Rapid speed | 12 m/min |

| Guide way | Linear guide way | |

| Transmission | Ball screw (∮ 38) | |

| Servo motor power (KW) | 1 | |

| Feeding movement of vertical (Z axis) | Rapid speed | 6 m/min |

| Guide way | Linear guide way | |

| Transmission | Ball screw (∮ 40) | |

| Servo motor power (KW) | 2 | |

| Ratio | 1:2 | |

| Maximum drilling thrust (N) | 23989 | |

| Max storke (mm) | 450 | |

| Positioning precision | ±0.1mm | |

| Repeat precision | ±0.04mm | |

| Verticality Accuracy | ≦0.05/300 mm | |

| Tool length | 170 ~300 mm | |

| Work table | T slot distance(mm) | 500 mm |

| Manual clamps | 4 T-slots | |

| Coolant system | High pressure coolant | |

| Quantity of chip - conveyor | 1 | |

| File transfer software for (DXF to G, M code) | Standard | |

| Power supply | 3 ø,220V,40HP | |

| Air pressure | 4 kg/cm² | |

| Machine dimension(L x W x H) mm | 5027x3690x2860 | |