- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Features

- Specifications

- Option

- Video

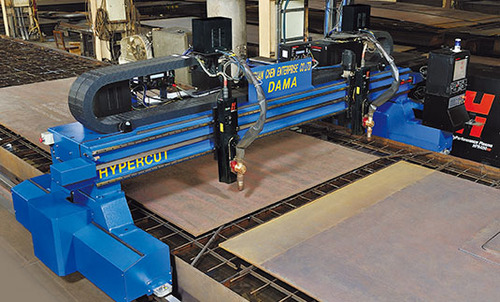

- Gantry design for heavy duty: Ensuring, both precision and reliability.

- Two full sized saddles, running on longitudinal guide rails: Giving high precision and durability.

- Equipped with high performance AC servo drive system: Positioning and contouring speeds up to 18 M/min.

- Linear guide for transverse precision and durable.

- 300mm width transverse guide, stability and precision even with heavy torch suspension units.

- Transverse energy feed chains: Giving efficient transportation of hoses and cables.

- Hypertherm High-End CNC controller EdgePro, ArcGlide plasma height sensor and HPR Hyperformance Autogas plasma as standard.

- Phoenix software built-in cut charts for automatically setting process parameters.

- Built-in CutPro™Wizard easy use.

- 15" Glass touch screen and Windows XPe operation system.

- RAM≥1GB、SATA hard drive、two USB ports、two Ethernet ports and RS422、RS232 ports.

- Software utilities: Part Program Support (PPS), Remote Help, networking, Autogas support.

- DXF import, and simple shape nesting.

- Option ProNest software for plasma True Hole cutting.

| Model | HyperCut 2500 | HyperCut 3100 | HyperCut 4000 | HyperCut 5000 | HyperCut 6000 | HyperCut 7000 | HyperCut 8000 | HyperCut 9000 |

| Effective cutting width (A) | 2500 mm | 3100 mm | 4000 mm | 5000 mm | 6000 mm | 7000 mm | 8000 mm | 9000 mm |

| Rail span (B) | 3500 mm | 4100 mm | 5000 mm | 6000 mm | 7000 mm | 8000 mm | 9000 mm | 10000 mm |

| Effective cutting length | 6500 mm +(X) | |||||||

| Rails length | 9000 mm +(X) | |||||||

| Cutting speed | 1~6000 mm/min | |||||||

| Rapid speed | 18000 mm/min | |||||||

| Power supply | 3 phases, 220V, 50~60Hz, 5KVA or on request | |||||||

CNC controller

|

||||||||

| Option | 1.Oxy-Fuel cutting kit:

|

|

| 2.Add Motorized Oxy-Fuel torch | 3.Oxy-Fuel cutting torch height sensor (capacitive) | |

| 4.Zinc Powder marking torch | 5.Warter spray | |

| 6.Electrical ignition unit | 7.Rail's extension unit : Per 3000mm/unit (X) | |

| 8.Air Scribe | 9.ProNest 2019 software for plasma True hole cutting. | |

| 10. Hypertherm HyPerformance Plasma : XPR-170,XPR-300,HPR-400XD,HPR-800XD | ||