- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Features

- Specifications

- Option

- Video

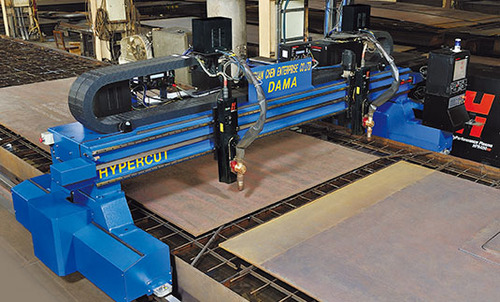

- The portal of the HYPERCUT is made from an extremely strong and rigid structure, designed to meet the requirements of high definition plasma applications.

- The water type cutting table is integrated with the machine or option fume suction cutting table.

- The optuion fume suction table there are 2 layers for table, upper for cutting area, lower one for sealed fume suction channel, easy to clean the cutting dross & pick up the parts & ensure the fume extraction performance in optimization.

- The machine longitudinal and transverse axis drives with rack, pinion and liner guide to do direct drive, especial the synchronized double side drives for the longitudinal axis, ensure the machine high speed traveling under stability.

- Extra loading flame cutting torch was available, option with a flame cutting kit, up to 100mm for thicker carbon steel plate cutting.

- Recommended option for outer bag type filter system, customer can prepare it locally or DAMA can provide the total solution for fume collecting solution.

- Edge Connect CNC controller, SensorTHC plasma torch height sensor and XPR hyperformance with surecut technology.

- Option ProNest 2019 nesting software for plasma true hole cutting.

| Model | HYPERCUT 1530 | HYPERCUT 1560 | HYPERCUT 1830 | HYPERCUT 1860 | HYPERCUT 2030 | HYPERCUT 2060 | ||

| Effective cutting width | 1524 mm | 1524mm | 1800 mm | 1800 mm | 2000 mm | 2000 mm | ||

| Effective cutting length | 3100 mm | 6100 mm | 3100 mm | 6100 mm | 3100 mm | 6100 mm | ||

| Machine space (W x L) mm | 3000 x 4500 | 3000 x 8000 | 3300 x 4500 | 3300 x 8000 | 3500 x 4500 | 3500 x 8000 | ||

| Longitudinal drive | Dual AC Servo Motor/Rack / linear guide | |||||||

| Transverse drive | AC Servo Motor/Rack / linear guide | |||||||

| Cutting Speed | 100~6000 mm/min | |||||||

| Rapid speed | 18000 mm/min | |||||||

| Plasma torch Height sensing control | Smart THC | |||||||

| Plasma cutting capacity | 1~50mm, Refer to plasma | |||||||

| Plasma gas | Refer to plasma model | |||||||

| Power supply (CNC use) | 3 phase, 220V, 60Hz, 5KVA | |||||||

| Power supply (plasma) | Refer to plasma model | |||||||

| Water type table as standard | ||||||||

CNC controller : Hypertherm Edge Connect

|

||||||||

| Option | 1. Oxy-Fuel gas cutting kit

|

|||

| 2.Zinc powder marking torch | ||||

| 3.Water table with air bag / fume suction table | ||||

| 4.ProNest 2019 software for true hole cutting. | ||||

| Plasma | HYPERTHERM | XPR-300(300A) XPR-170(170A) MAXPRO200(200A) HPR-400XD (400A) | High performance plasma auto/manual gas | |