- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Home

- Our Brands

- Koike

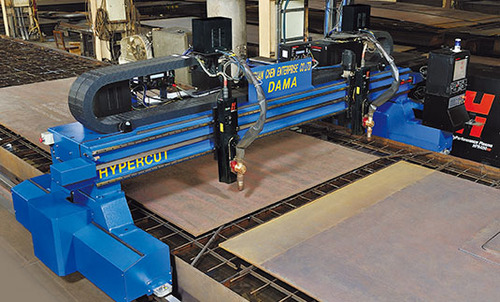

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

CAN IS FULLY INTEGRATED INTO OUR PSDAQ SMART CONTROL SOFTWARE. IT IS SIMPLE TO USE AND EASY TO CONFIGURE INPUT/OUTPUT CHANNELS IN THE MAIN CAN SCREEN. THE DYNAPACK CAN ACCEPT UP TO 4 CAN DEVICES (#1-#4) WITH EACH DEVICE HAVING SEPARATE SETTINGS SO ONE DEVICE CAN FOR EXAMPLE CONNECT AT 500K-BITS/S WHILE THE OTHER DEVICE CONNECTS AT 125K-BITS/S.

Individual CAN outputs can be directly enabled or disabled from this screen

Features of the CAN interface:

- USB powered

- Galvanic isolation to over 500V with opto isolated USB to CAN communication

- Approximate Dimensions: 105 x 60 x 35mm, 230g

- Supports 11-bit (CAN 2.0A) and 29-bit (CAN 2.0B Active)

- Supports all standard bit-rates. Custom bit-rates in the range of 10K to 1M supported

- Standard (CiA® 303-1) 9-pin D-Sub CAN interface connection

- Receive messages on the CAN bus, log and display real-time in PS DAQPLUS Software

- Transmit messages from the Dyno software to other devices on CAN, including Dyno’s measured torque