- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Home

- Our Brands

- Koike

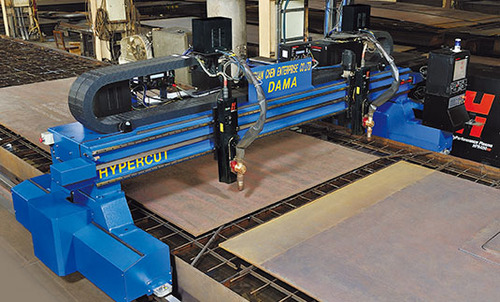

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

Description

EDGE® Connect, Hypertherm’s Computer Numeric Control (CNC) platform, delivers unmatched reliability, powerful embedded capabilities, and a high level of customizability. Based on our proprietary, industry-leading Phoenix® CNC platform, the system offers new, advanced software features – including ProNest® CNC automatic nesting delivering SureCut™ technology – along with enhanced hardware.

For easy set up, changes, and upgrades, EDGE Connect CNCs can be configured in the field with software specific to the cutting machine application. The easy-to-use system combines advanced cutting performance with an intuitive graphical interface, and supports plasma, oxyfuel, and waterjet applications.

- With Patented CutPro® Wizard, even new operators can be cutting production parts in less than five minutes

- On-screen Software Operator’s Console (Soft OpCon) allows easy setup and operation of cutting station and manual motion

- Integrated communications with plasma and torch height control systems deliver automated and expert control using installed factory or custom cut charts

- Custom cut charts can be created and controlled in the part program or made available to the CutPro Wizard

- EDGE Connect runs on the Windows® 10 Enterprise operating system

ProNest® CNC nesting

- Easy-to-use touch screen interface, machine operators can create nested part programs and obtain optimal cut quality without extensive training.

- Directly imports DXF, DWG, CAM, DGN, and CNC simple shapes.

- Embedded SureCut™ technology maximizes performance through embedded expertise. Patented True Hole® technology with process verification ensures all operator variables are properly set.

- Pattern Array Nesting for a single part with process optimization included.

- True Shape Nesting module for multiple parts (included when using EDGE Connect and ProNest on the same internal network; available as a paid option for users without Pronest or an internal network connection).

Customizable performance

- Designed to accommodate a broad range of applications, such as plasma (including cutting, marking, bevel, pipe/tube), oxyfuel (including bevel), and waterjet

- Available in 2 hardware configurations to best align with cutting machine manufacturer needs

- Optional Sensor™ plasma torch height control mechanics (Sensor THC)

Point-of-use configuration

- Basic and advanced process control for plasma, oxyfuel, and waterjet

- Integrated Sensor THC and bevel

- ProNest CNC True Shape Nesting

- PLC Connect™ (Programmable Logic Controller)

OEM customization

- PLC Connect is embedded in the CNC for additional capabilities tied to I/O signals, position, cutting state, and error conditions; IEC61131 compliant

- OEM customization of the on-screen software operator’s console for control of unique system tools and features though use of a C# Application Program Interface (API)

Quick, easy installation

- Requires only a single EtherCAT® cable for all motion and I/O signals from the CNC, dramatically simplifying system wiring and reducing installation time

- Communication to Hypertherm’s HyPerformance® plasma systems is accomplished through EtherCAT connectivity directly to the cutting system.

Flexible configurations

EDGE Connect

|

The smallest of the CNC configurations, the EDGE Connect offers the greatest flexibility for machine integration. Cutting machine OEMs provide the touch screen and any operator switches. |

|---|---|

EDGE Connect TC

|

Integrates the EDGE Connect CNC into an industrial enclosure with a 495 mm (19.5″) touchscreen. A hardware operator’s console with switches for start, stop, program and manual speed control, raise/lower torch and joystick is included for easy operation. |