- Home

- Our Brands

- Koike

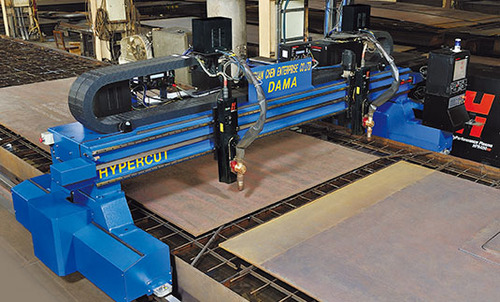

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

Description

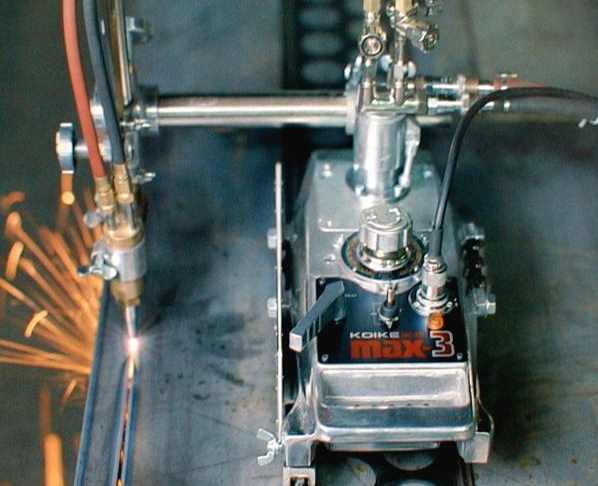

The IK-12 Max 3 is the premium product of our assortment! This motorized hand cutting machine allows different types of oxy-fuel/plasma cutting and automated welding. There are three major parts to the system. The advanced motorized carriage, a cutting torch unit, the plate track and accesories. All serving as independent units, the customer can choose the system for his specific requirements. The Speed Control utilizes an exclusive KOIKE Double Cone Stepless Speed System, which functions with a condensor motor rotating at regular speed to prevent heat and voltage problems. In addition, the condensor motor rotates at a constant low speed ( 1,500 rpm), extending the service life of bearings.

Features

- Outstanding performance

- Unrivaled robust and heat-proof machine

- Excellent traction

- Steady travel due to a well balanced center of gravity

- Very high number of operation hours (more than 5000 h) due to the double cone drive

- Speed (80-800 mm / min.) High Speed (240-2400 mm / min.)

- Heat protection shield on the cutting side and the base plate

- Gas and plasma cutting as well as automated welding

- Cutting area of 0,5 to 600 mm

- Easy maintenance

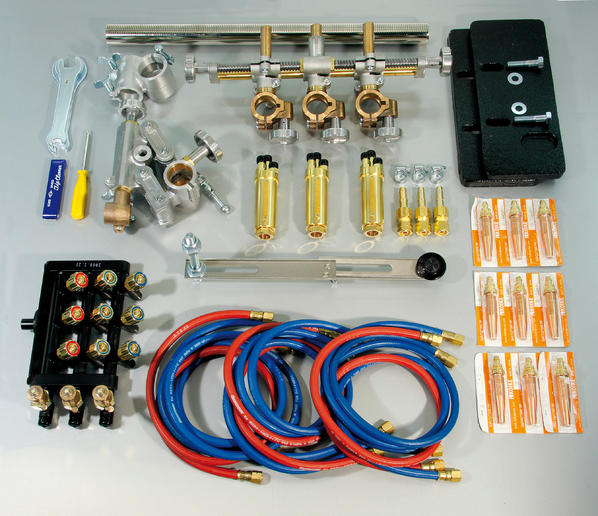

Scope of delivery

- Base machine IK-12 Max 3

- Connecting lead

- Operation instructions

Technical specifications

| IK-12 Max 3 | |

| Cutting thickness | Depends on the torch set |

| Cutting speed | 80-800 mm / min (50Hz), 100-1,000mm / min (60Hz) |

| Transmission System | Double cone speed system |

| Motor | Condenser type Induction Motor 9/10W(50/60Hz) |

| Total length | 430 mm |

| Track width | 160 mm |

| Type of gas | Acetylene, propane |

| Weight | 11.0 kg (only main body) |

Available accessory

| TORCH SET ( IK-12 Max 3 ) | ||||

| S-100 | S-200 | SP-100 | SP-200 | L-100 |

|

|

|

|

|

| Torch set S-100 for vertical and bevel cutting… More › | Torch set S-200 for vertical, V-, Y-, X- and bevel cutting.… More › | Torch set SP-100 with parallelogram motion link.… More › | Torch set SP-200 for vertical, V-, Y-, X- and bevel cutting. The… More › | Torch set L-100 for thick plate vertical & vebel cutting.... More > |

| SP-300 | SP-400 | EPOCH-300 | EPOCH-600 | |

|

|

|

|

|

| Torch set SP-300 with parallelogram motion link for vertical, V-, Y-… More › | Torch set SP-400 with parallelogram motion link for vertical, V-, Y-,… More › | Torch set EPOCH 300 for vertical and beveling cutting with a material… More › | Torch set EPOCH 600 for vertical and beveling cutting with a material… More › | |