- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

- Home

- Our Brands

- Koike

- Dama

- Hypertherm

- Plasma systems

- Powermax65 SYNC plasma cutter

- Powermax85 SYNC plasma cutter

- Powermax105 SYNC plasma cutter

- XPR300 plasma cutting system

- MAXPRO200 plasma system

- XPR170 plasma cutting system

- HPR cartridge & XD technology upgrade

- Powermax45 XP plasma cutter

- Powermax30 XP plasma cutter

- Powermax125 plasma cutter

- HyPerformance HPR400XD

- HyPerformance HPR800XD

- Powermax30 AIR plasma cutter

- Plasma systems

- GYS

- ELECTROPNEUMATICS

- Yanase

- Dynapack

- About Us

- Contact Us

Description

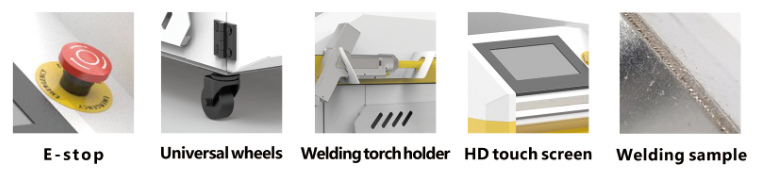

The new 3 in 1 generation machine has triple functions of welding, cutting and cleaning. New design, small size, flexible and convenient, 70% less floor space than traditional laser welding. The operation is simple, newcomer can get started quickly and weld easily. 380V industrial model, low welding current, high efficiency and energy saving. Qualified raw materials, excellent quality. Large LCD touch screen, upgrade experience, clear data display. Three sides ventilation holes, keep colling for a long time welding. Double drive wire feeder, more stable wire feeding. Optional double wire system for high power machine. A new designed welding torch, lens can be replaced easily, light grip and untiring using. The Side welding torch holder prevent internal optical fiber of the welding torch from being damaged. 10m welding torch cable + 10m gas hose, more freedom for long- distance operation at larger stations. Multiple safety protections such as overheat protection, chiller protection, laser warning, etc.

Technical parameter

| Model | HGLW-1500E | HGLW-2000E | HGLW-3000E | |

| Input Voltage (V) | 3P AC 380 | |||

| Operating Mode | Welding/cutting/cleaning (3in1) | |||

| Laser Resonator Brand | Hugong/Maxphotonix | |||

| Laser Wavelength | 1070~1090 nm | |||

| Welding/Cutting/Cleaning Torch | Hugong Wobble laser welding head (with wire feeding part) | |||

| Double wire feeding function | / | / | Optional | |

| Swing Mode | Linear | |||

| Compatible wire diameter | 0.8, 1.0, 1.2, 1.6(2.0, 2.5 optional) | |||

| Suitable wire reel specifications | 5kg/10kg/25kg | |||

| Maximum wire feeding speed m/min | 6m/min | |||

| Adjustment range of weld seam width | 1~5mm | 1~5mm | 1~5mm | |

| Cooling method | Water cooling | |||

| Welding torch body weight | 0.8kg | |||

| Cable length | 10m | |||

| Available gas | Ar/N2/Co2 | |||

| Maximum power consumption | 7kW | 11kW | 15kW | |

| Laser Safety Protection Level | Class 4 (GB 7247.1, IEC 60825-1) | |||

| Processing material and welding | SS / MS:1~4 | SS / MS:1~6 | SS / MS:1~8 | |

| Penetration range(mm) | AL:1~4 | AL:1~5 | SS / MS:1~6 | |

| Applicable sheet thickness (mm) | SS / MS:1~5 | SS / MS:1~6 | SS / MS:1~8 | |

| AL:1~4 | AL:1~5 | AL:1~8 | ||

| Machine Size (LxWxH) | 915*490*775 mm | |||

| Net Weight | Machine 120Kg, Wire Feeder 13.5Kg | |||

Parts